|

|

|

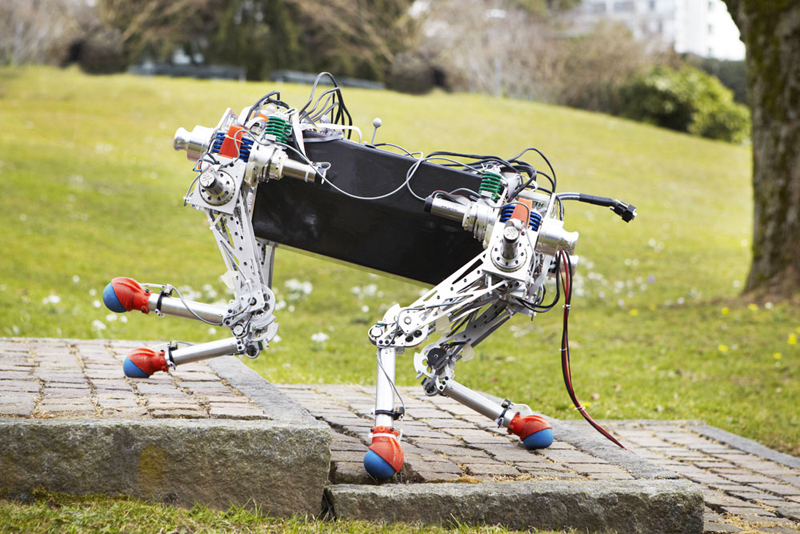

Photo: Starleth Quadruped, Autonomous Systems Lab, ETH Zurich |

A Facebook friend recently posted a short video showing a team of horses pulling a stalled tanker truck out of a snowbank. The four horses were harnessed in parallel to two doubletrees, an elaborate amount of tack to have on hand for an emergency procedure. And the animals pulled well together, suggesting they were a team sent to the accident site from a nearby farm. The video was shot in Central Pennsylvania, which is small-farm country, but I would also have guessed somewhere in Eastern Europe—anywhere people might still work with trained horse teams. Certainly, our factory farms out West use tractors, and fairly large, high-tech, GPS-guided ones at that.

But all of this is reflection after the fact. What struck me in the moment of watching those four horses pull the front of the truck back around on the snow- and ice-glazed road was how surefooted they were. The horses didn’t need snow tires or chains, or salted roads, or even a smooth road surface, as our wheeled vehicles require. And that gave me a vision of the future—or one possible future.

The origin of the wheel as a transportation device dates back to Mesopotamia in about 3,500 B.C. This makes it a fairly late invention, compared to the domestication of crops and farm animals, and about contemporaneous with smelting of copper, one of humanity’s first metals. As suggested at the link above, inventing the wheel required a good set of metal tools to work wood, because you’re not going to make useful wheels out of quarried stone you’ve hammered into shape with some harder kind of rock. You need chisels and planes to fit and join sections of plank into a stable, round form, because you can’t just saw off the end of a log and get four wheels of almost identical dimensions, or not dependably. And you need drills to bore a hole for the axle, and a draw knife to shape the end of the axle to fit inside the hole. You also need to invent and affix a locking nut or cross peg to the outer end of the axle, in order to keep the wheel from working off and rolling away. That’s a lot more sophisticated than just shaping some round logs for rolling one of Pharaoh’s stone building blocks across a pathway of smoothed, compacted sand.

But the wheel you make also needs a fairly level, smooth surface to roll on—a flat riverbed or graded road. As any Jeep owner will tell you, driving across open country littered with chuck holes, downed logs, and medium-sized boulders is hell on wheel rims and tires. In desert conditions, you can probably stick to level ground and the occasional dry wadi. In the more hilly and wooded parts of the Mediterranean and Europe, the Romans built elaborate, paved roads so they could move marching men and supply wagons quickly to access conquered countries. In America, we pour millions of cubic yards of concrete and roll out tons of asphalt to maintain our roads, which lace together every household, town, city, and state. We nail or bolt millions of miles of steel ribbons onto wooden or concrete crossties embedded in gravel to guide the wheels of our railroads. We put a lot of work into all this infrastructure to keep those wheels of all dimensions and materials turning.

Interestingly, the indigenous peoples of North and South America—those who walked across the Bering land bridge during the last Ice Age—never invented the wheel and so had no need of roads. The Incas created a fairly sophisticated empire based on footpaths through the mountains. Other cultures used dogs for carrying and hauling their burdens—that is, until the Spanish brought horses into the Western Hemisphere and let enough of them escape to form wild herds that the natives could catch and tame.

The wheel is considered one of the six “simple machines,” along with the lever and the wedge.1 It has also forced our modern technology into a very specific pattern. The earliest source of non-animal, non-muscle mechanical power was the water wheel—which was the thinking man’s adaptation of the wagon wheel. The thinking must have been something like: “If the wheel turns when it travels along the road, what would happen if the road were to run under the wheel? Like that stream there, where the water runs down the valley?” That and the windmill—another adaptation of the wheel—meant that our earliest machines imparted a circular motion to all our tasks. The first grain mills not powered by human muscles rubbing the kernels between one stone and another used water or wind power to drive large stone grinding wheels. When steam was first applied to pumping out mines and then to driving riverboats, the up-and-down, in-and-out action of the cylinder and its piston had to be converted to the more familiar circular motion through a crank shaft and a series of gears.

The first electric motors mounted magnets in a circle around a shaft and spun them inside an armature of other magnets. But, as demonstrated by magneto-hydrodynamic (MHD) generators for making electric current, and linear induction motors (LIM) and solenoids for applying it, spinning shafts are not the only way to use electricity. However, the concept of an “engine” was so firmly fixed on the idea of circular motion and rotating shafts that almost all our inventive effort went into making these things go round. And certainly, a spinning crankshaft or rotor mated well with turning the wheels of our “horseless carriages.”

Perhaps things would have come out differently if those indigenous American cultures had advanced far enough, without early influence from the Old World, to discover and make use of electricity. Then, inspired by human and animal muscles, the leverage in elbows and knees, and their experience of grinding corn and cocoa beans under oblong stones going back and forth on the flat-rock metate, the first electricity use might have been linear instead of circular.

So the vision I had, watching those horses drag the truck out of the snowbank, was that we may one day return to that linear motive force—but not by reverting to the use of animal muscles. With our advances in computer technology and sophisticated control systems, people are now working on robotics and other automata—things that move by themselves. And right now, the science seems to be at a fork in the road.

Many robots roll around on wheels, but they all require smooth surfaces, flat floors, and inclined ramps or elevators instead of stairs to go from one floor to the next. True, there are neat ways to make a trio of wheels rotating around a common axle climb a set of stairs—but that’s a one-time application, designed for stair step with particular dimensions of elevation and depth. That triple wheel totally breaks down if the gadget encounters a step that’s too tall or has to move across a boulder field. The Mars rovers use cleated wheels, but they must stick to the wind-swept plains and the fortuitous ancient streambed.

Various laboratories are now working on walking robots, which use linear motors based on pistons, pulleys, tension cables, and other straight-line drives to work the joints in hypothetical hips, knees, and ankles. They require a sense of balance—usually through gyroscopes and strain gauges—to remain upright. And they must be coupled with sophisticated control systems, usually combining visual and tactile sensors, to place their feet accurately and in proper order. From what I can see in the video clips that occasionally get out to the public, these robots can walk or run on level surfaces and up modest inclines—about the same achievement as a wheeled vehicle.

One of my articles of faith is that we are not at the end of our discoveries in any field. In many applications, linear motors, computer controls, and sensor systems to emulate animal models are lagging behind rotary motors driving shafts and wheels. But we are still in the early stages of discovery and development in robotics. I can envision a future—not perhaps in the next hundred years, but certainly within the next thousand—where cyber-controlled devices will be so ubiquitous and the use of electro-mechanically adaptive materials that emulate muscles will be so common, that the most useful vehicle for human and cargo transport will not be wheeled. Instead, when we must travel over the ground, instead of flying, we will use multi-legged transports. Being as surefooted as a horse or mule, they won’t need a prior investment in the infrastructure of flattened surfaces, graded roadbeds, or steel rails. Riding on or inside one of these cyber-creatures would mean that your route and destination are not limited to a layout of prepared pathways. You could travel cross-country, or even climb the side of a mountain, if you chose.

Of course, by then we humans will probably have paved the surface of the Earth and even extended our roads a good ways out beyond the low-tide mark. But on the other planets we likely will not have—or take the time to make—such conveniences. A mechanical horse would go a long way on Mars or Titan. And its only disadvantage would be that, unlike a real horse, you can’t eat it if your supply of food packs happens to run out.

1. Classically, these six machines are the lever, wheel and axle, pulley, inclined plane, wedge, and screw. The definition of a simple machine is a device that changes the direction or magnitude of an applied force. But if you want to get mystical about it, the wheel and pulley are just different applications of the same invention, as are the wedge and the inclined plane. So definitions of the earliest inventions will vary.